The 8mm Nambu Project

George Spence was a locksmith at Blytheville AFB, Arkansas, when I arrived there – right out of basic training -- in November of 1971. A few months later there was a Q&A, in one of the gun magazines, on where to get ammunition for a WWII Japanese pistol; and the answer was ‘George Spence, 203 North Main, Steele, Missouri’ – Steele was only about 12 miles north of Blytheville, just across the state line. Well, I didn’t need any ammunition for a Japanese pistol, but did relish the opportunity of meeting someone who was to me a celebrity, as I had read his name in print in a gun magazine – so I called George and gladly accepted the invitation to visit his shop.

He was 41 years my senior; and in addition to being a locksmith, he had a side business of loading obsolete ammunition -- including the 8mm Japanese Nambu pistol cartridge. George and I got along great and I spent quite a bit of time in his shop over the next two and a half years – learning many things about guns and reloading. At the time, I didn’t have a clue that meeting George Spence, and other events that would occur later, would help define my career and significantly impact the shooting sports industry.

The process George used to make 8mm Nambu ammunition was very interesting! He started with fired 38 Special M41 military cases and used a hand-operated copper tubing cutter, with a stop added, to shorten them to Nambu length -- while he watched television at night; pretty clever. The next step was at his lathe, where he reduced the diameter of the rim slightly and cut in an extractor groove. A friend had made him a carbide die to reduce the neck from 38 special to 8mm (.357 bullet to .323 bullet) and form the shoulder. The only problem with his formed cases was that the head diameter was only .376 and 8mm Nambu chambers are designed for ammunition with a head diameter of .412 – so some of the cases would split when fired. George’s position on this was simple “upon firing, some will split; if they do, no problem; if not, they’re reloadable.” Personally I doubt if any were ever reloaded. He cast lead bullets from a Hensley & Gibbs four cavity mold and lubed and sized them in an old Lyman 45 lubrisizer. I bought a box of this ammo for my cousin Charlie Maple from St. Louis, who had a Nambu pistol, and he and I shot a couple of magazines through it one Sunday afternoon.

When we started the gun shop in 1977, one of the guns my brother Jerry put in as part of his equity was an old Remington Model 8 in 25 Remington. This was a decent, collectable gun, but it was still sitting on the rack that fall when we got a sale flyer from Hodgon that included some surplus 30 Remington police ammunition at $2.00 for a box of 20. Being a pretty serious handloader, I had George Nonte’s book, The Home Guide to Cartridge Conversions, and knew that we could make both 25 Remington and 8mm Japanese Nambu pistol cases from 30 Remington; so we bought everything they had (about 10,000 rounds), and got started. George Spence was 70 by this time; he was retired but still making ammo, and was kind enough to loan us his Hensley and Gibbs bullet mold – encouraging me to “go man go!” Thinking about forming the necks the same way that George had, we inquired about a custom die with Frank Snow at Carbide Tool and Die in Covina, CA. He reminded us we could get steel forming dies from RCBS, that would work just fine, and suggested that we talk with Starline Brass, which was located nearby at the time. (More about that later.)

Now having all the tooling lined up, we pulled the bullets and dumped the powder, creating a couple large buckets of primed 30 Remington Brass. Not having a lathe, only a drill press, and needing an efficient method of shortening the cases to Nambu length, brother Jerry came up with the idea of using a 41 Caliber Lyman bullet mold to grip the 30 Remington brass – the lube groove fitting nicely into the extractor groove of the case. A two inch slotting saw and arbor was recommended and supplied by older brother Marion, who was an engineer. Now, gripping the case in the bullet mold and carefully sliding the mold through the jaws of the vise on the drill press, with the arbor spinning the cutoff saw, we completed this first step in the Nambu project – shortening the cases.

The RCBS form dies created the neck, though with considerable effort, as the brass was quite thick and hard that far down on the case; however, they looked great! The case walls around the bullet were too thick of course, but RCBS also supplied a reamer to open the neck to the correct diameter. Then, we cast and lubricated the bullets and loaded the ammunition – using cousin Charlie’s Nambu pistol to work up the loads. We advertised in Shotgun News and the interest was quite gratifying; everything was soon sold out.

The old NSGA show was in Chicago in 1978 (The S.H.O.T. Show wasn’t created till ’79). I walked up to the Federal Cartridge booth and pitched them to make us a run of 8mm Nambu brass. They declined, but walked me over and introduced me to Jim Bell at Brass Extrusion Laboratories, Limited; a company that specialized in making brass for obsolete cartridges. At the B.E.L.L. booth I found Jim to be a very friendly and optimistic fellow, and he made it clear right away that they would be delighted to make us some Nambu brass, so we wrote a contract for 500,000 cases to be delivered six months later. This was my first lesson about lead times and delays in manufacturing schedules. The cases began arriving in March of 1980, only eight months behind schedule.

We had started advertising in July, expecting the first deliveries in August and had a considerable quantity of backorders when the first cases arrived in March. To compound things, brother Jerry had decided in January that he wanted to sell his half of the company and move back to the home area and buy a farm. He left in March, just after having set up the newly acquired Dillion RL-1000 machine on which the Nambu was to be loaded.

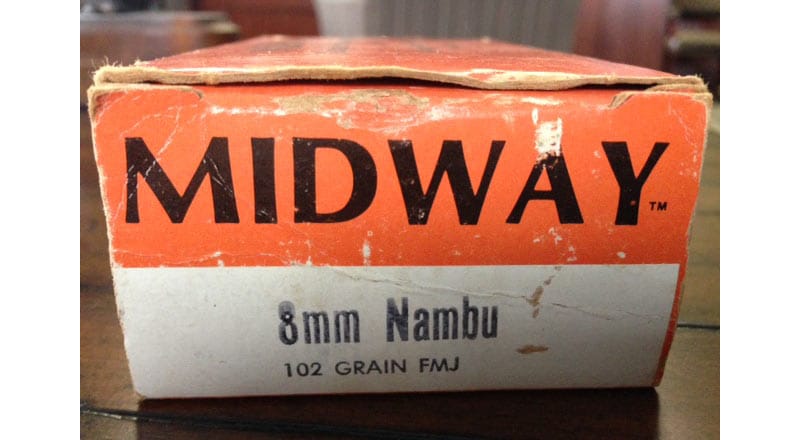

Hornady made the full metal jacket bullets for us. I personally specified the weight of 102 grains and diameter of .320, without a cannelure – to be true to the original specifications. In retrospect, they probably should have been about .325 and cannelured – for best results. In early testing, I found some of the bullets would push back when hitting the feed ramp and that the accuracy was terrible. Working with Hornady, their tool room made us a 7/8" x 14 collet die with a three-point stab crimp to secure the bullets in the neck of the case, as the last die in the tool head. This also held the bullet long enough for the pressure to build and expand the bullet to fill the grooves in the rifling. Accuracy was fine after that.

Another problem to solve with the Nambu project, was the cartridge box. I liked the Winchester Styrofoam tray and the Winchester folks were kind enough to provide the name of the plant that made them. As it happened, Winchester had a density specification for these trays; during mold changes and shift start up, the plant produced a lot of trays that were not dense enough for Winchester -- so they offered to sell these to us at a very good price. All of the Nambu ammunition was packaged in these trays and we also began selling the trays with plain white boxes in September, 1980. With the success of the plain white cartridges, we then began offering plastic ammunition boxes, which were also a great success.

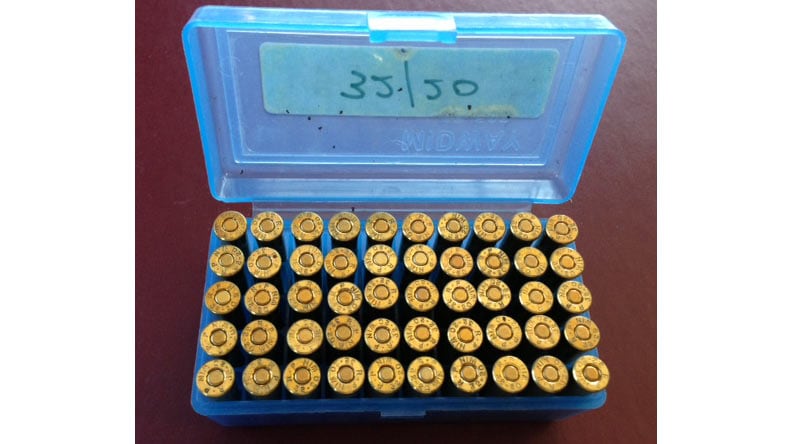

The first 30 days or so, after the initial delivery of brass, was pedal to the metal. I would arrive at the shop at 5:00 am and load ammunition till 7:00, then walk home for a quick breakfast with Brenda and the kids; then back to the shop and load Nambu till 9:00 am -- when it was time to open up the store for business. Russell, our 5-year old, went to school and Brenda and Sara, our 3-year old, would come to the shop and box up the ammunition. During the day, between Customers, I would ship the backorders. Store hours ended at six pm and I went home for a quick dinner, then back to the store to load ammo till 9:00 pm. With the RL-1000, I could load nearly 2,000 rounds of the unprimed brass per hour, which included filling the primer tubes, systematically weighing the powder charges after each 500 rounds and pulling out three rounds per 1000 for pressure testing – which Hornady did for us.

Back now to the earlier reference to Starline Brass. They had started up in mid-1970’s, and had been producing 38 Special and 357 Magnum brass for only a few years when we first made contact. They made no ammunition, only unprimed brass and didn’t have a distributor, only O.E.M. accounts. Our first order was for 200,000 357 Magnum cases, bearing the Midway headstamp. We advertised in Shotgun news and began to change the shooting sports industry forever. Starline added more calibers, Winchester began selling us bulk brass in 1984 and Remington in 1987. MidwayUSA is the grandfather of the bulk brass business, and it all got started as a spinoff from the 8mm Nambu Project.

The 8mm Nambu ammunition has all been sold and the Project is part of the history of MidwayUSA -- indelibly imprinted in my mind. By itself it wasn’t a home run, but the lessons learned and the spinoffs we developed helped change my career and forever change the shooting sports industry.